Race Car Suspension Design

Automotive Design

Project Info

Objective

Designed a race car suspension system suitable for drifting by achieving the following criteria,

- Added trail and reduced caster which adds more grip by increasing tire contact patch.

- Optimized camber ranging from -3 to -6.

- Adjustable Ackerman.

- 70 degrees depending on your wheel size and offset.

- Minimal bump steer in drift by perfecting tie-rod pitch angle.

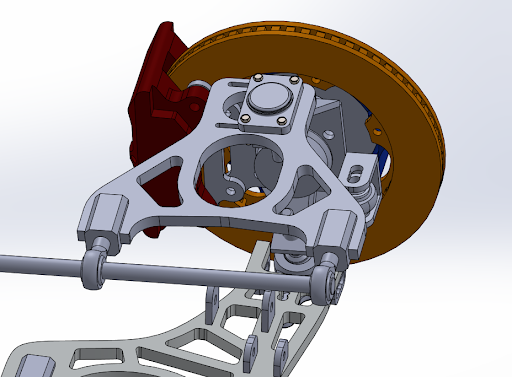

- The compact drop knuckle design makes for a lighter and stronger design.

- Chromoly Heim joints and spherical bearings with self-lubricating nylon race which are easily replaceable.

Solution

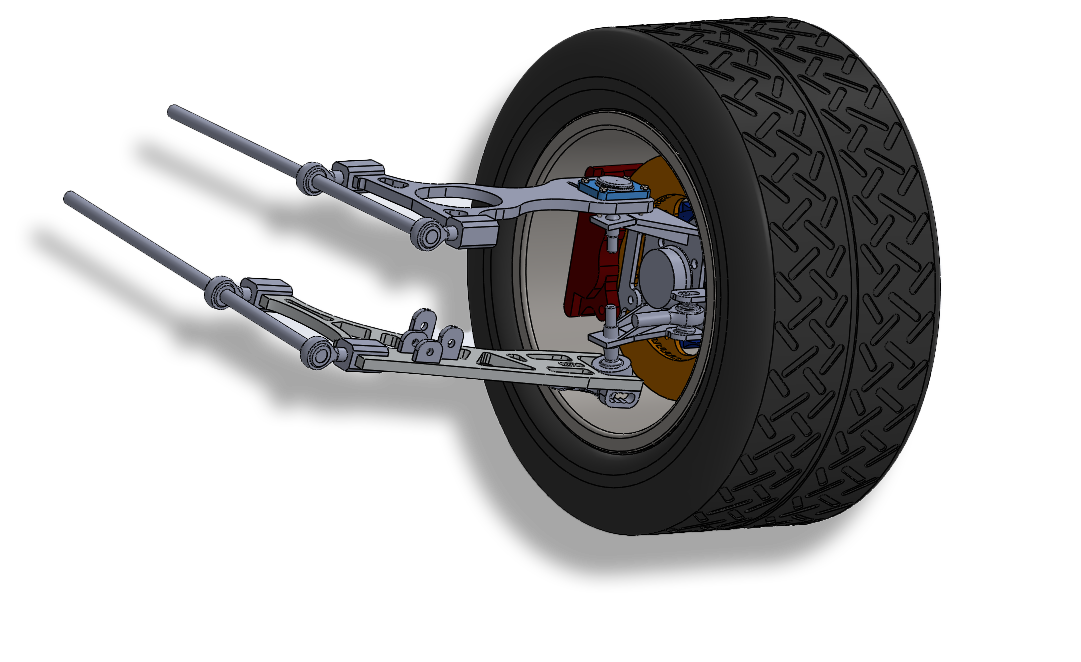

- Designed with CAD software.

- Designed the Knuckles and A-arms to be manufactured using laser cutting and welding.

- The following parts were custom designed,

- Knuckle

- Lower arm

- Upper arm

- For the brakes, Wilwood calipers and rotors were used.

- For all joints, 5/8″ Heim joints were used.

Results

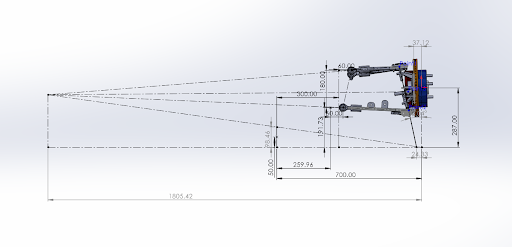

- Adjustable caster from 4.64 to 11.54 degrees.

- Adjustable camber from -1.9 to -8.26 degrees.

- 3 presets were designed for Ackerman.

- Custom-made knuckle with 0.25in thickness 7075 steel. All parts can be laser cut and welded together.

3D Cad designig

Design Criteria

CAD Software and Tools Used

- 3D modeling and Simulation using CAD

- Rendering Images

Design Guidelines and Standards

- All the calculations for the suspension design was done inside our company and according to the calculations we have designed the geometry

Manufacturing Methods Used

- Laser Cutting using CNC machine

- Welding